Tackling Plastic Waste Through Innovation: New Zealand’s Path to Sustainability

20 March 2024

The Aotearoa New Zealand government is taking sustainability seriously, especially around plastic waste. Back in 2001, the Ministry for the Environment produced a document: “A New Path for Plastic,” which shed light on the country’s intent to manage plastic waste. The problem was finding ways to do so, as plastic recycling, while traditionally the best option available, is severely limited in terms of the plastic types that it can be applied to, and the end product is typically inferior to its inputs.

With NILO, the country is taking meaningful steps towards delivering the government’s objective.

The Challenge of Building and Agricultural Waste

In 2023, New Zealand produced around 400,000 metric tonnes (MT) of plastic waste, of which only around 10% was collected for recycling, and only about half of that collection is processed within New Zealand. The rest of it ends up in landfill.

Additionally, a lot of the plastic waste would be unable to be recycled, even if it was collected, and these figures represent only a fraction of the total plastic waste produced annually that is accounted for. These numbers highlight just how little is being done to manage plastic waste, and why the matter is now of pressing importance.

NILO’s Binder Process: A Game-Changer

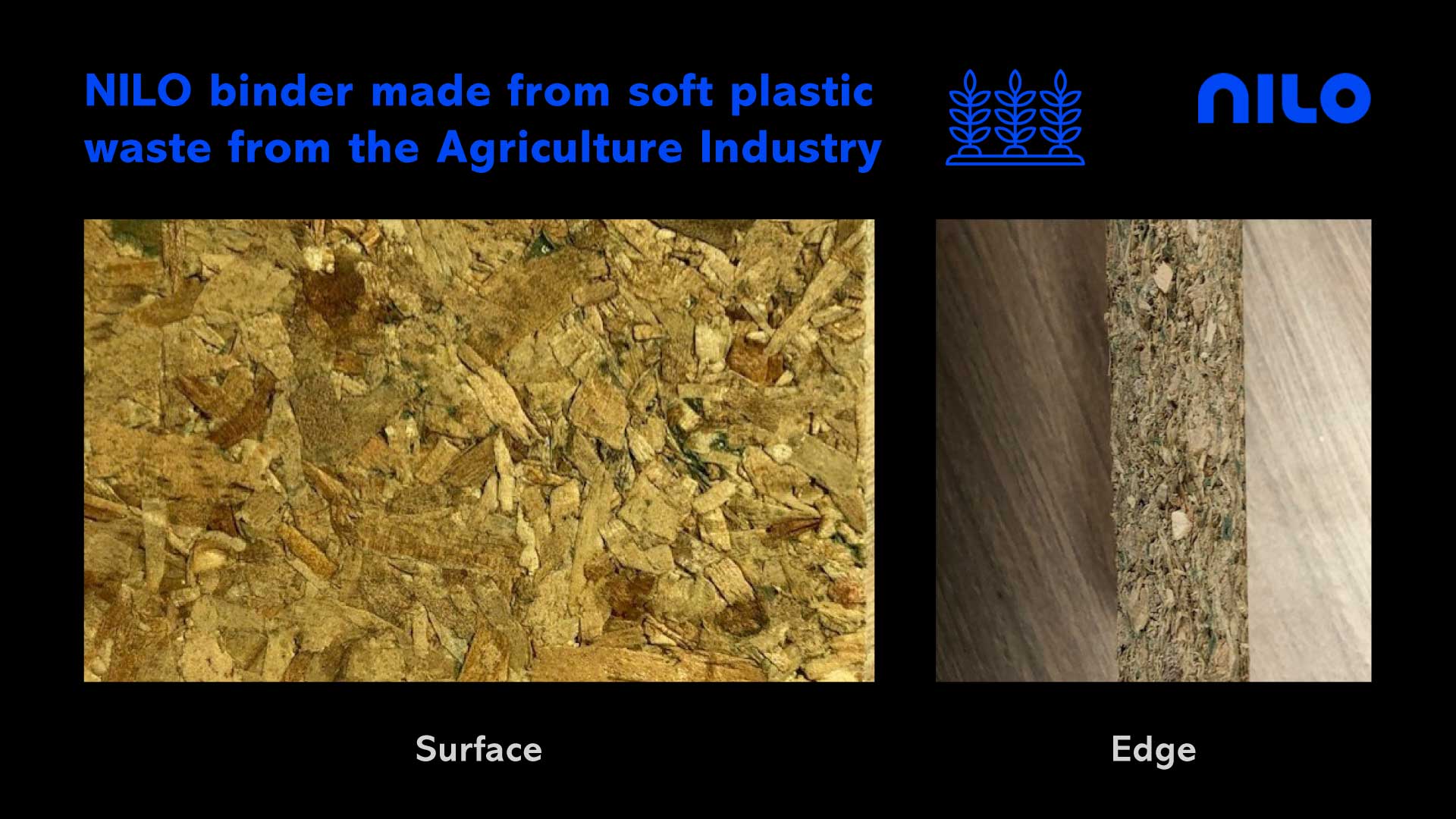

NILO offers a superior solution to addressing any form of plastic waste, by converting it to an adhesive that can be used as a binder in wood board manufacturing. This innovative process repurposes, rather than recycles, soft plastic waste from sectors such as building and agriculture. In the first instance, this saves the need to transport the plastics to Asia for recycling, as had previously been standardised. It keeps the jobs and economic activity in New Zealand.

Secondly, the process produces far better-quality products than recycling can achieve.

NILO’s Innovations in Action

Take, for example, these products that NILO’s solution has been part of manufacturing.

Two sectors where plastic waste has been a particularly sticky issue for New Zealand are the building and agricultural sectors. The waste from these plastics is not typically recyclable, and so the only solution has been to find a way to dispose of the waste.

NILO’s technology has been adapted to create high-quality boards from this waste waste. In total, the company can manufacture its adhesives by consuming around 5,000 metric tonnes MT of building wrap and 6,000 MT of agricultural plastic. These boards are as durable and effective as they were when made from the incumbent binding agent, but contribute to a fully circular economy, as these boards are themselves recyclable, meaning that the NILO adhesive is less likely to become landfill the second time around as well.

Investing in plastics research and innovation is not just good for the environment by bringing a truly circular economy approach to plastic waste. It also makes good sense for the New Zealand economy to turn plastic waste into a resource. Ready access to cost-effective offshore processing has limited investment in New Zealand’s own, local systems. Recycling ironically creates too much waste, and there are some severe limitations on plastics produced this way – the degradation of recycled materials is significant. The NILO solution offers an alternative to all of this, with the opportunity to invest in New Zealand manufacturing.

With all of this as context, and these examples of NILO’s innovations in action proof that the innovation is effective, there is a growing case to further expand our processing capabilities and innovate further, as we find more ways to generate plastic waste repurposing that is safer for us and our environment.